Our Products

Azab Bearing Is Proud to introduce highly recommened and branded Products

Tensioner Bearings

The wear-bearing bearing prevents the belts from slipping and reduces friction while the engine is running, and good lubrication prevents you from doing much maintenance. This unique design was made to increase the life of the car's engine and maintain the belts, which leads to more energy savings

Wheel Hub Bearings

Also known as 2nd or 3rd generation wheel bearing, it’s designed to allow rear wheels, especially in passenger cars, to turn on an axle even under heavy loads. Apart from having components such as the wheel bearing, flange, and anti-lock braking system (ABS), it has built-in sensors that allow location tracking as well as speed monitoring via global positioning system (GPS).

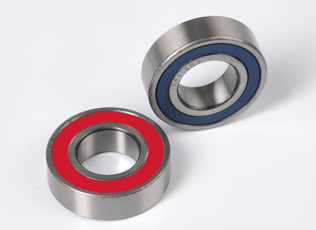

First Generation Wheel Bearing

Commonly used in cars’ front wheels, most wheel bearings manufactured today are pressed together as an assembly: front race bearing set, center race bearing set, and outer race with seals on both front and rear race. Belonging to the angular contact ball bearing family, their key components are the outer ring, two inner rings, rolling elements, and cages.

.jpg)

Clutch Release Bearings

A specific type of thrust ball bearing, clutch release bearings’ applications are dependent on the type of engine used. Specifically designed to transfer power from the gearbox to the engine, they can take axial load and perform well at maximum speed or even in heavy-duty transmissions.

Alternator Ball Bearings

A type of ball bearing with a polyamide cage, alternator ball bearings are designed to withstand speed or temperature fluctuations while supporting the generator in supplying energy for a vehicle’s electrical requirements and battery. Connected to the pulley as well as to the tensioner bearing, this type of ball bearing is sealed and can take combined loads.

Air Conditioner Ball Bearing

Designed to accommodate combined loads while withstanding vibration, air conditioner ball bearings facilitate the transfer of energy from the engine to the compressor. Their key elements are one outer ring, one inner ring, rolling elements (balls), and cages that are engineered to reduce noise output with increased tolerance to heat. These bearings have raceways in both inner and outer rings which are placed together in the direction of the bearing axis. Always sealed, this bearing type has a longer service life due to less risk of contamination, thus giving reliable air conditioning service to vehicles.

Water Pump Bearings

With a simplified structure, a water pump bearing is a double support auto bearing without the inner ring hold. They feature a groove for a rolling element directly made on the shaft while the outer rings of its two bearings are combined and closed by rubber seals. Water pump bearings consist of two design types: 1) The ball-ball which has two rows of balls 2) The ball-roller which has one row of balls only (a one-row roller). In the same loading capacity conditions, the radial dimensions are usually lower compared with heavier loading capacity conditions.

Wheel Bearing Kits

With about 1,200 part numbers supplied for the OE application, the SNR wheel bearing kit range is designed to provide the right components depending on the vehicle type to ensure a longer-lasting wheel bearing and cost-effective maintenance.

Mostly manufactured in France, these kits are equipped with Active Sensor Bearing (ASB) technology that enables bearing speed measurement for a safer driving experience.

Truck Wheel Bearings

Offering solutions for axle, wheels, and transmission components, these bearings are trusted by OE manufacturers worldwide due to their durability and longer service life. Available in tapered roller bearings (TRB) or hub units, this range has increased resistance to shock damage and enables even load distribution with less friction.