Our Products

Azab Bearing Is Proud to introduce highly recommened and branded Products

Precision Bearings

Combining Japanese technology and European service range, precision bearings are engineered for high speed and high-performance applications. With improved grease retention capabilities, these emit lesser heat and noise levels while increasing equipment efficiency and reliability. Current designs include special holes found between spacers known as air cooling nozzles which enable precision bearings to continuously operate at very high speeds and extreme temperatures without the fear of failure or downtime.

Sumitomo Eccentric Bearings

A closer look into Sumitomo eccentric bearings Found inside a Sumitomo Cyclo Drive, eccentric roller bearings are designed to reduce the speed of the input shaft thereby increasing torque or the rotational “pull” or “push” linear force. Consisting of two bearings in a misaligned position, this bearing type enables equal distribution of load to all power transmitting parts to ensure maximum shock load tolerance, longer service life, and increased machine productivity. Found inside a Sumitomo Cyclo Drive, eccentric roller bearings are designed to reduce the speed of the input shaft thereby increasing torque or the rotational “pull” or “push” linear force. Consisting of two bearings in a misaligned position, this bearing type enables equal distribution of load to all power transmitting parts to ensure maximum shock load tolerance, longer service life, and increased machine productivity.

Tapered Roller Bearings

Key elements of tapered roller bearings (TRB) include the outer ring, inner ring, rollers, and a cage. These bearings have tapered inner and outer ring raceways between each aligned tapered rollers enabling them to accommodate combined radial and axial loads. Their unique features are higher load ratings, adjustable mounted clearance, and the ability of the outer ring to be mounted separately from the inner ring assembly.

Spherical Roller Bearings

A spherical roller bearing (SRB) or self-aligning roller bearing consists of a locking feature, an outer ring, and an inner ring which is enclosed by the former in the axial direction. This bearing permits angular rotation to a central point in two orthogonal directions. Spherical roller bearings support a rotating shaft in the bore of the inner ring which must move not only rotationally but to a certain angle. Most spherical roller bearings have an outer raceway that is a portion of a sphere making them internally self-aligning. Each roller has a curved form correctly angled to the rotation’s direction which conforms closely to the inner and outer raceways. The housing gives this type of bearing a high radial load-carrying capacity.

Self-aligning Ball Bearings

The inner ring of this type of bearing has two raceways and the outer ring has a single spherical raceway with its center of curvature coincident with the bearing axis. Therefore, the axis of the inner ring, balls, and cage can deflect to some extent around the bearing center. Consequently, minor angular misalignment of the shaft and housing caused by the machining or mounting errors are automatically corrected. Generally, self-aligning ball bearings feature a tapered bore for mounting using adapter sleeves. These are particularly suitable for applications where considerable shaft deflection or misalignment is to be expected. Self-aligning ball bearings have the lowest friction of all rolling bearings, enabling them to run cooler even at high speeds.

Plummer Block

Plummer blocks are bearing housings supplied without any bearings. They are usually meant for higher load ratings and corrosive industrial environments. The terms pillow block and plummer block are used interchangeably in certain parts of the world. The disruptive strength of plummer block varies depending on its type, nature, and direction of a load working on it, as well as the flatness of the surface to which it is installed. Split the plummer block housings are generally used for self-aligning ball bearings, barrel roller bearings, and spherical roller bearings.

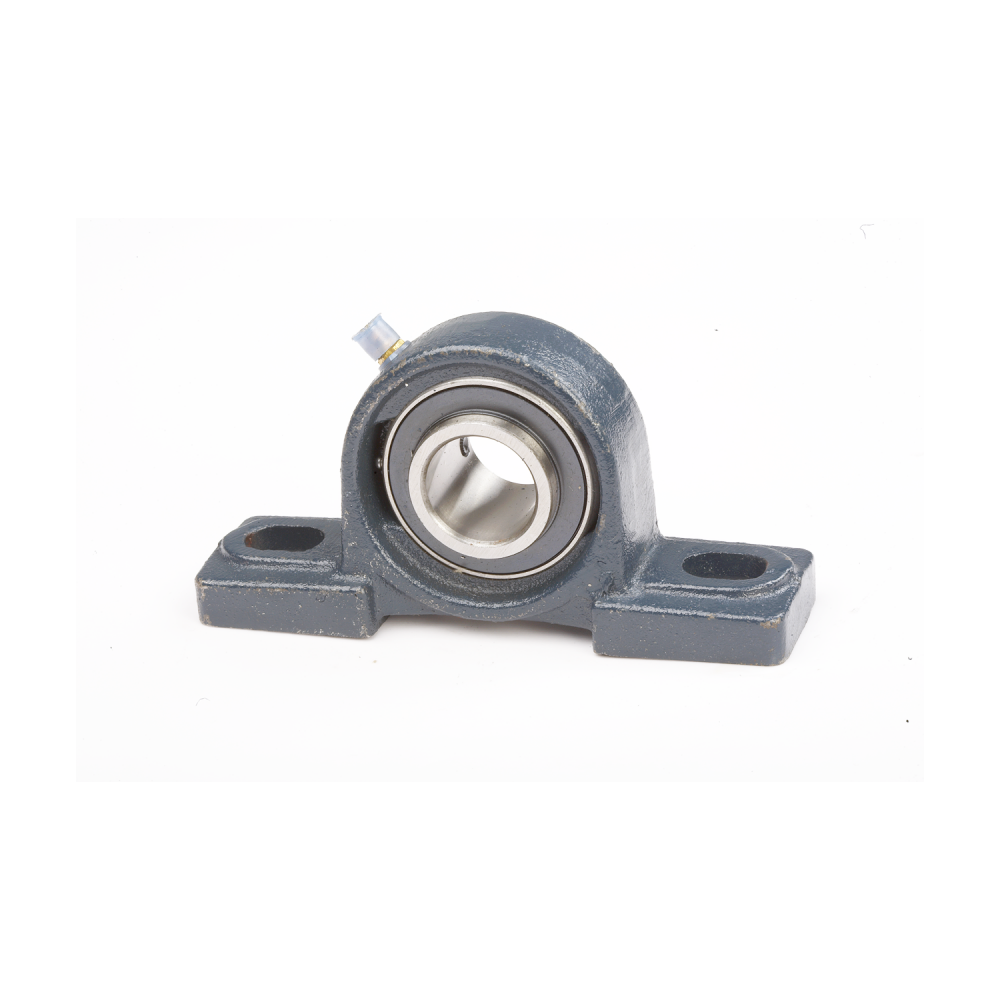

Pillow Block

Pillow blocks are mounted plain or roller bearings used to provide support for rotating shafts with the mounting surface on a line parallel with the axis of the shaft. These refer to the housings that have a bearing fitted into them, thus the user need not purchase the bearings separately. A pillow bearing is generally mounted in cleaner environments, these are typically meant for lesser loads in general industrial applications. Pillow blocks are deployed in a variety of configurations. Unlike other bearings, they are pre-engineered to be self-lubricating and are designed with a reservoir to store lubricant for smooth operation. The fundamental application of pillow blocks involves safety. Their outer ring remains stationary while allowing rotation of the inner ring.

Needle Roller Bearings

The needle roller bearing is a variation of the cylindrical roller bearing. The main difference is in a roller design capacity. The roller quantities are higher and the diameter of each is thinner than usual. Full complement needle roller bearings do not have a cage. In this type of bearing, one roller pushes against the other holding everything in place. Even though needle roller bearings have a low cross-section, they have a high radial load capacity and are exceptionally suitable for bearing applications where radial space is limited. Ensure top performance by getting bearings only from a reputable needle roller bearings supplier.

Deep Groove Ball Bearings

Deep groove ball bearings (DGBB) are the most common types of bearings that are durable and easy to maintain. Having a simple structure consisting of an outer ring, an inner ring, a ball, and a cage in various sizes, these are available in single and double-row designs as well as in open and sealed variants. Compared with the other kinds of bearings, DGBB have a very low frictional coefficient and high-speed limit which makes them unable to endure high impact and heavy loads.

Cylindrical Roller Bearings

Key elements of cylindrical roller bearings include inner race, outer race, cage, and rollers. Cylindrical shaped rollers are kept evenly spaced by the cage which guides their turning movement on the flat surface of the two races. Some types have flanges or ribs projecting from the edge of one or both of the races. This housing supports the rollers while permitting limited free axial movement of the shaft in relation to the housing. The unique features of cylindrical roller bearings are their high capacity under radial loads, accurate guiding of the rollers, and limited free axial movement. Due to having a relatively high radial load capacity, cylindrical roller bearings are suitable for high speeds. Double-row cylindrical roller bearings meanwhile have high radial rigidity.

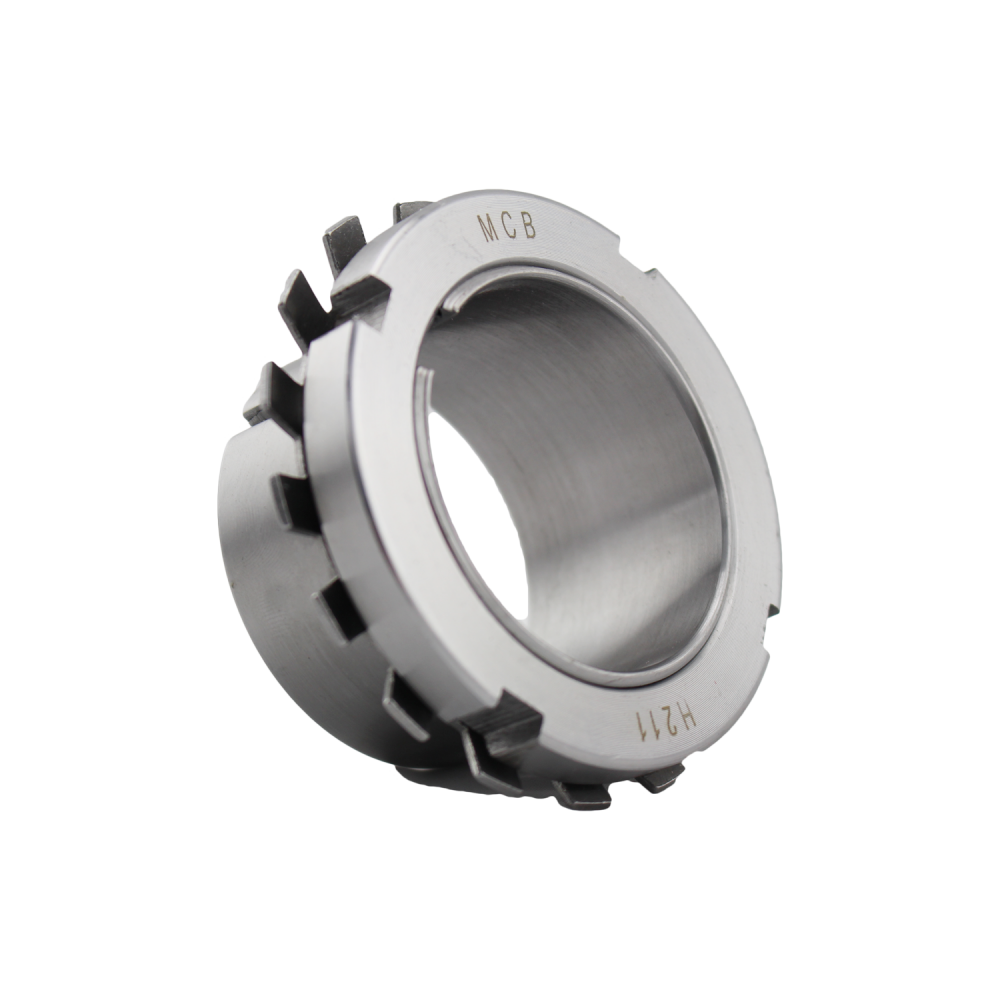

Adapter Sleeves

The key elements of adapter sleeves include the tapered adapter bush, lock nut, lock washer or retainer. Adapter sleeves feature axially slotted sleeves with cylindrical bores, a tapered outside surface, and male screw threads at the narrow ends used with lock nuts and lock washers for the mounting of bearings with tapered bores on cylindrical outside surfaces of shafts. Adapter Sleeves are also called Pull-type sleeves. Adapter sleeves are the most commonly used components for placing bearings with a tapered bore onto a cylindrical seat as they can be used on smooth or stepped shafts. They are easy to mount and require no additional location on the shaft. When adapter sleeves are used on smooth shafts, the bearing can be located at any position on the shaft. When used on stepped shafts, together with an abutment ring, bearings can be accurately positioned axially, and the bearing dismounting will be facilitated.

Angular Contact Ball Bearings

Angular contact ball bearings have raceways in the inner and outer rings that are displaced with respect to each other in the direction of the bearing axis to accommodate combined loads (simultaneously acting radial and axial loads). Additionally, the contact angle of the bearing is matched to the relative proportions of each– the larger the contact angle, the higher the axial load supported, but the lower the radial road. They are generally used in pairs, triplex sets, quadruplex sets, or multiplex sets since an axial component is generated when a radial load is applied.

Thrust Ball Bearings

Thrust ball bearings consist of two precision chrome steel washers (rings) and a ball complement spaced by a bronze retainer. Because the bearings can be separated, the mounting is simple. The washers and ball as well as the cage assembly can be mounted separately. Single-direction thrust ball bearings can accommodate axial loads in one direction, thus locate a shaft axially in one direction. These must not be subject to any radial load. Double-direction thrust ball bearings can accommodate axial loads acting in both directions and can serve to axially locate a shaft in both directions. Products are all from trusted ball bearing suppliers.